IHU Internal high pressure forming

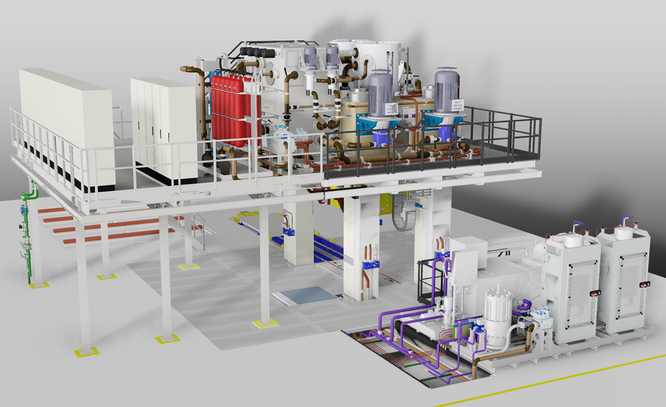

A common method for shaping pipes and profiles is to expand through internal pressure up to 3,000 bar. In current projects, we have been able to prove our competence again regarding the IHU process, with or without integrated functions as punching. In addition to the hydraulic special press, we also include the high pressure transmitter and all the sizes of a production line from the blank stock preparation to the washing machine and down to the stacking. Operations such as sawing, drilling and punching are just as much a part of the package as transfunctions, robots and handlings.

At IHU, the tappets and plate holders are coupled. The closing stroke is effected by the small dimensioned ram cylinder in the rapid stroke. After the tappet is locked against the head piece, the closing force is applied by the closing cylinders. In this pressing concept presented here, it proves to be advantageous that the upper die is supported against 3 rigid elements, namely, plunger, bolt and head piece. The resistance moments of the 3 units add up and guarantee the smallest deflection. Locking force can be applied via the closing cylinders arranged below where it is needed.

In case of a double plate, the plate inlet in the flange can be optimally controlled by means of a partially dosed closing force.